Reduce operating costs with smart automation

Supporting asset management with smart automation can result in additional savings. You can see the challenge we have faced with this in two examples.

Problem

How can hundreds of pumping stations be monitored with minimal effort? And how can maintenance costs be reduced without sacrificing quality?

Solution

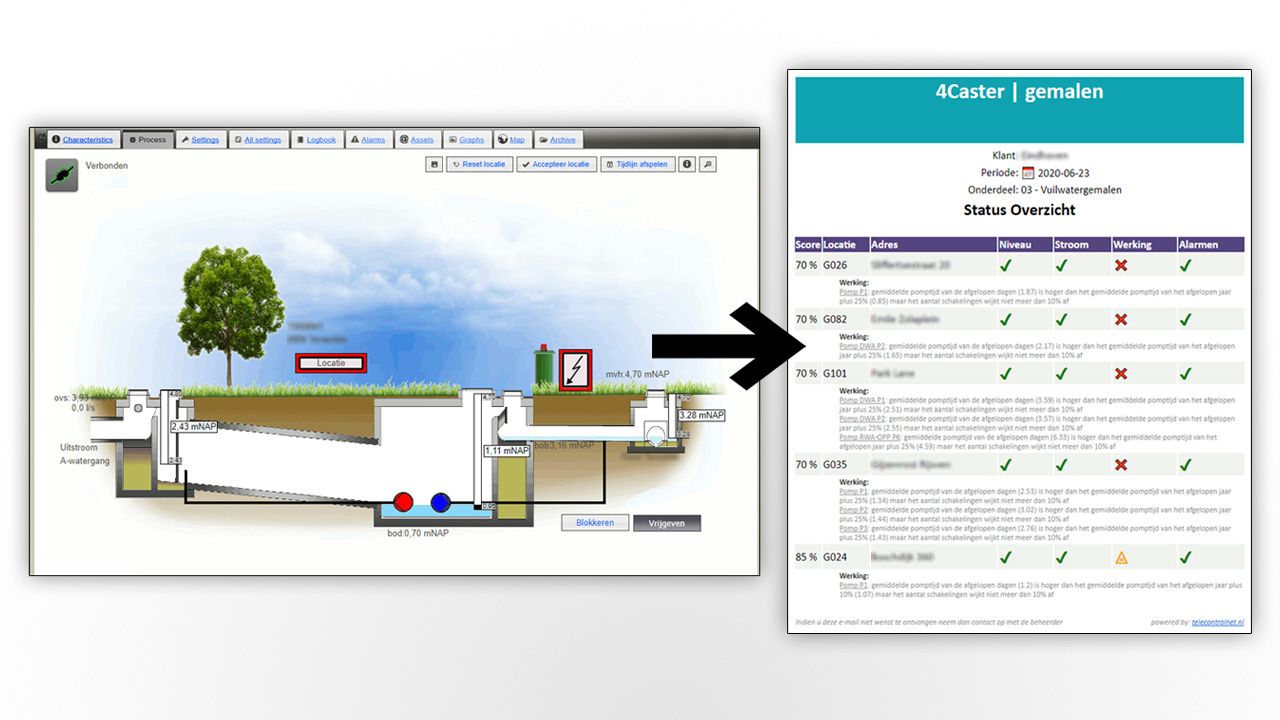

We do this using the generation of smart messages for operators. The image below shows an example of such a message. It shows how operators are automatically informed about the functioning of hundreds of pumping stations. The performance of a pumping station is indicated on a scale from 0- to 100%-functionality. The smart messages are generated periodically by the 4caster module in TeleControlNet. With these messages, operators can see in an instant how all pumping stations function, without having to browse through a central system to look up relevant information (if any available at all). If an operator wishes to receive more information about a pumping station, he will be presented with an extensive technical location report at the touch of a button.

The second gain can be achieved by switching from periodic to conditional maintenance. In conditional maintenance, the pump station itself indicates that there is a need for service. This is done by automatic analysis of measurement data with the 4caster module. We have learned from experience that the average maintenance interval can be extended by up to 50% in this way.

The starting point for the 4caster analysis is the reliability of data sets. We collect this reliable data in our end-to-end IoT solution with edge controllers (see Wikipedia "edge computing"). This approach is unique in the traditional telemetry world. The Inter Act edge controller is called TeleController and it continuously collects measurement data with small log intervals, making the reports from our 4caster very reliable.